KOKI

- Home

- Project Detail

JU-R4S

KOKI | Heat Curable SMT Adhesive

- Best suited for keeping large components from fallimg off during double-sided reflow.

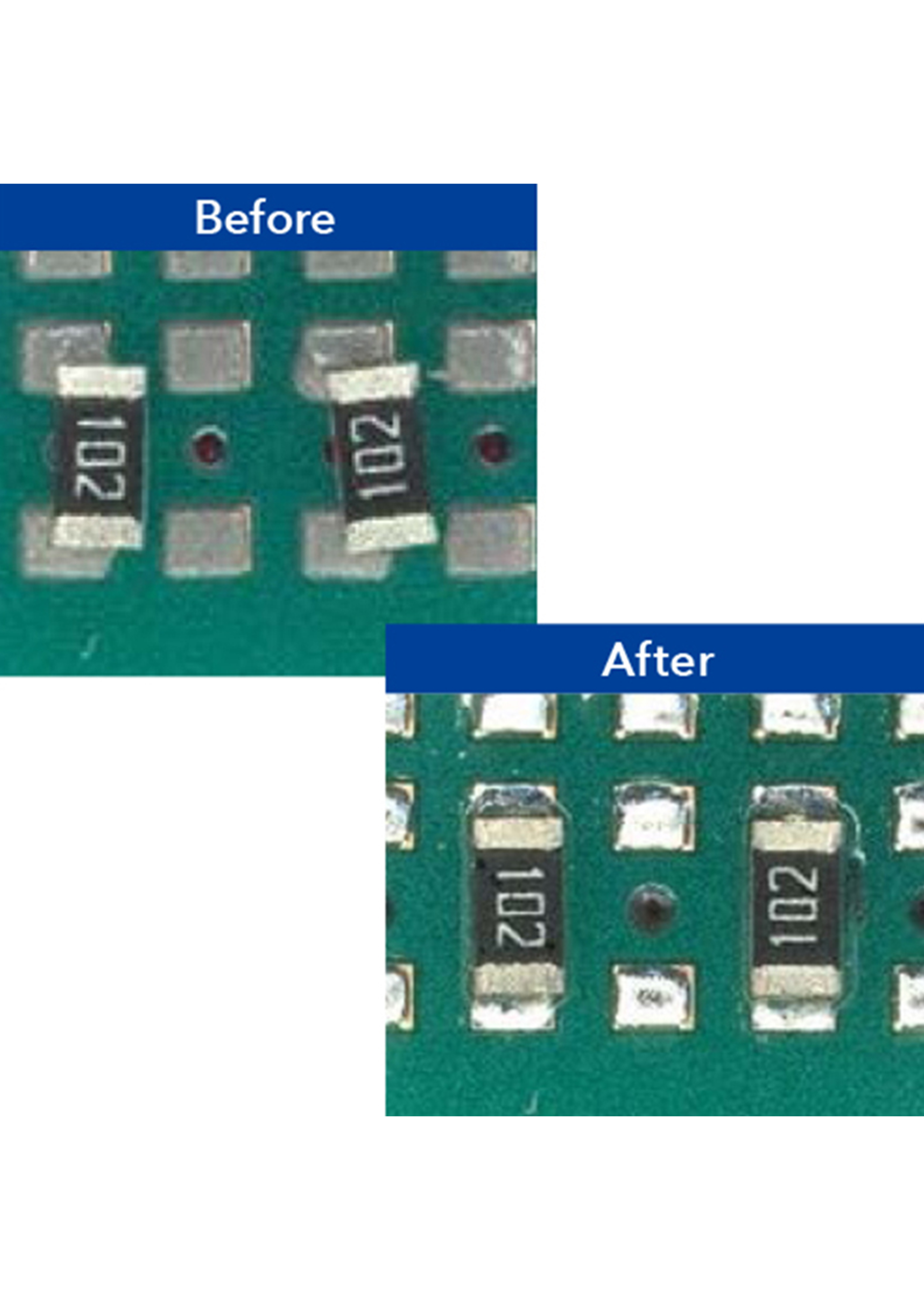

- Helps keep components on the board from falling, shifting, or floating during reflow. Using a conventional adhesive with solder paste can result in the lifting of components during reflow because the adhesive cures before the solder paste melts. JU-R4S maintains its fluidity while the solder is molten and facilitates setting of the components.

- Allows solder paste self-alignment at reflow. JU-R4S is designed to commence curing after the solder (SAC305) has melted. Therefore, JU-R4S does not hinder self-alignment of components that may occur when the solder has melted.

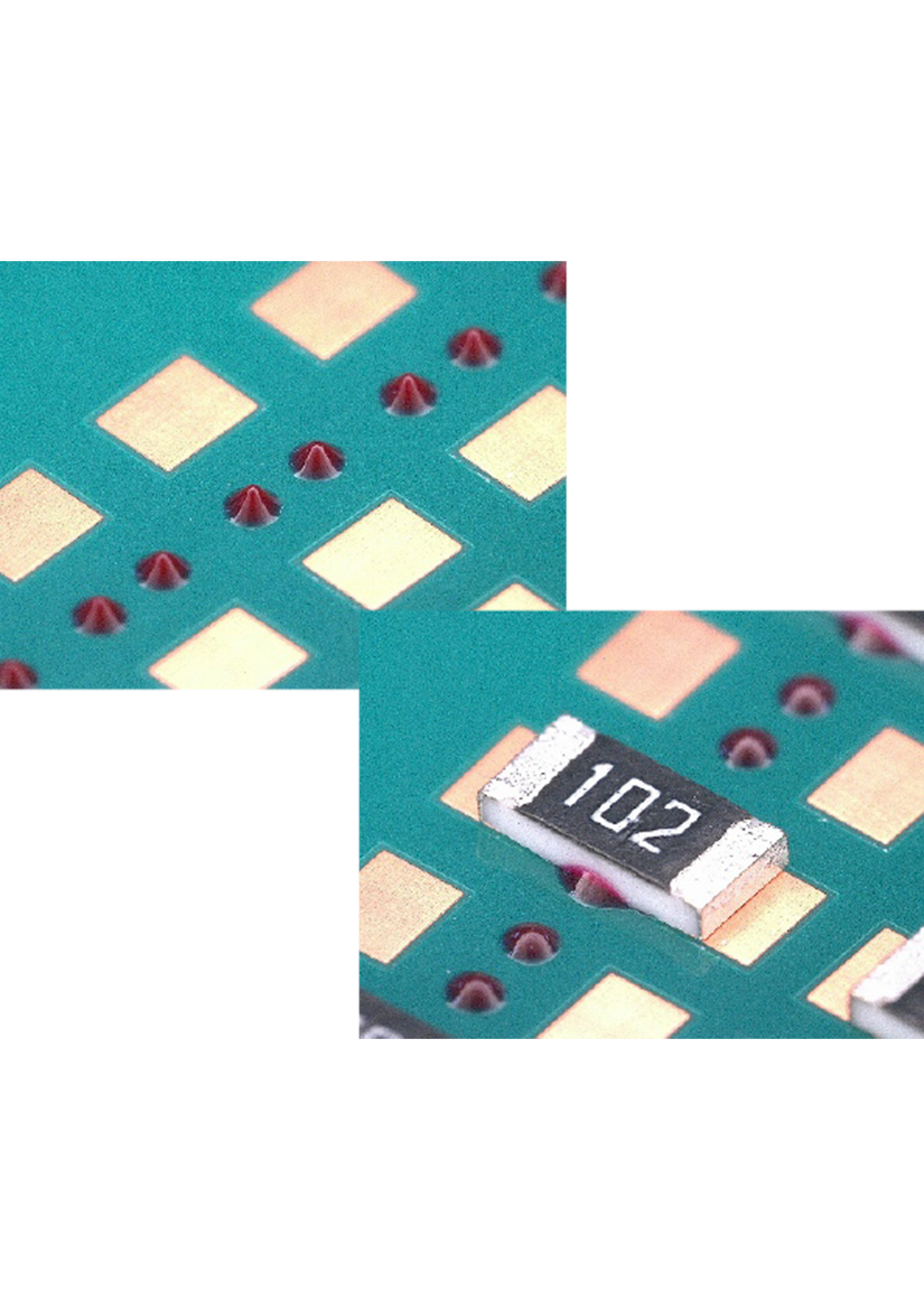

- Stable dispense shape and superior electrical reliability after curing. Dispensability of JU-R4S was improved by reducing the viscosity while shape retention was also improved by optimizing the TI value. The resultant tall deposits ensure contact and adhesion even for tall components.

- Specifications

| Model | JU-R4S |

|---|---|

| Composition | Epoxy resin |

| Viscosity(Pa.s) | 50 |

| Shelf life (0-10℃) | 6 month |

| Product Category | Heat Curable SMT Adhesive |

| State / Color | Paste, red |

| Transition Temperature(℃) | 99℃ |

Same Category Products