KOKI

- Home

- Project Detail

JU-90LT-3

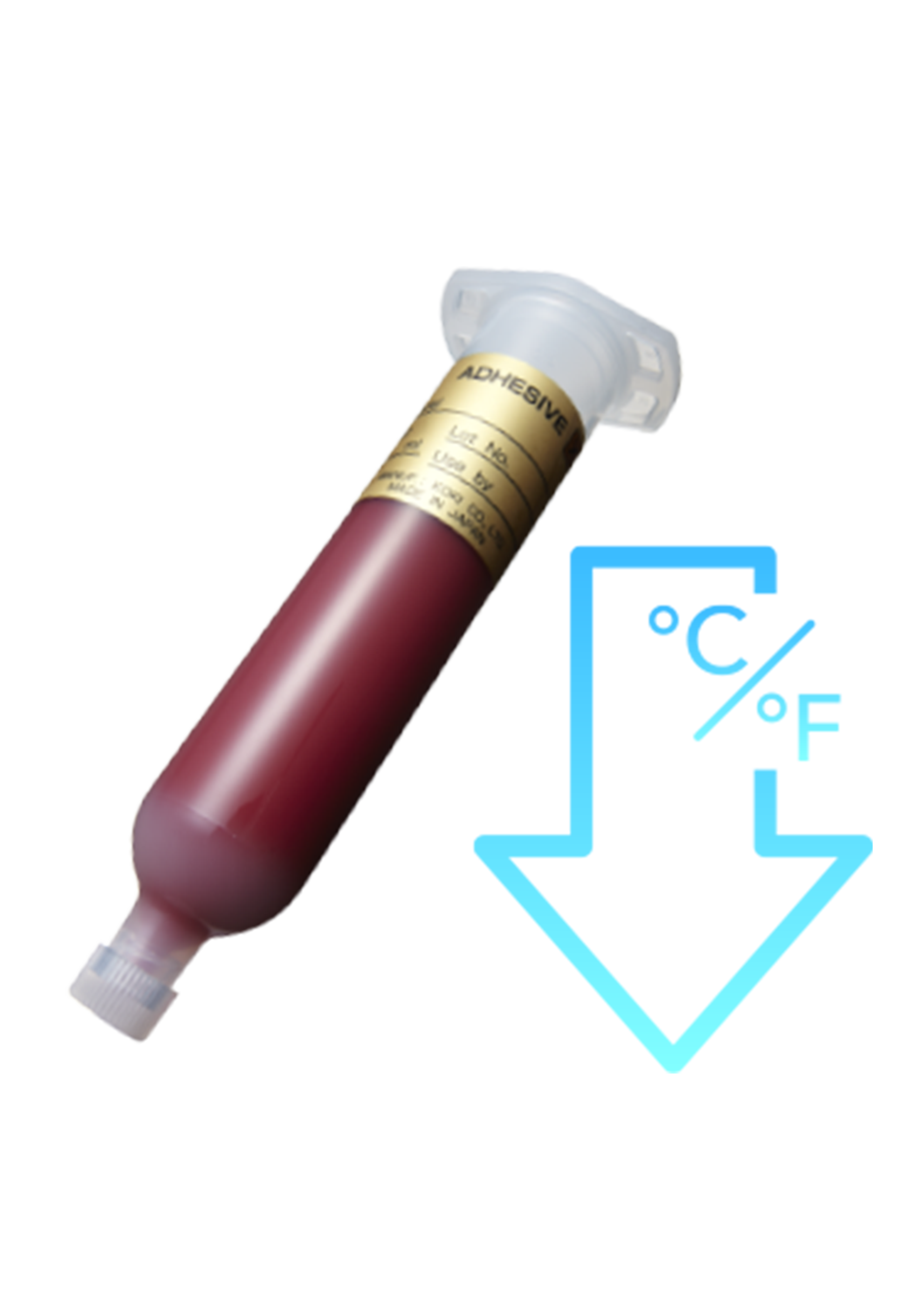

KOKI | Heat Curable SMT Adhesive

- Reduces thermal stress on the components and board.

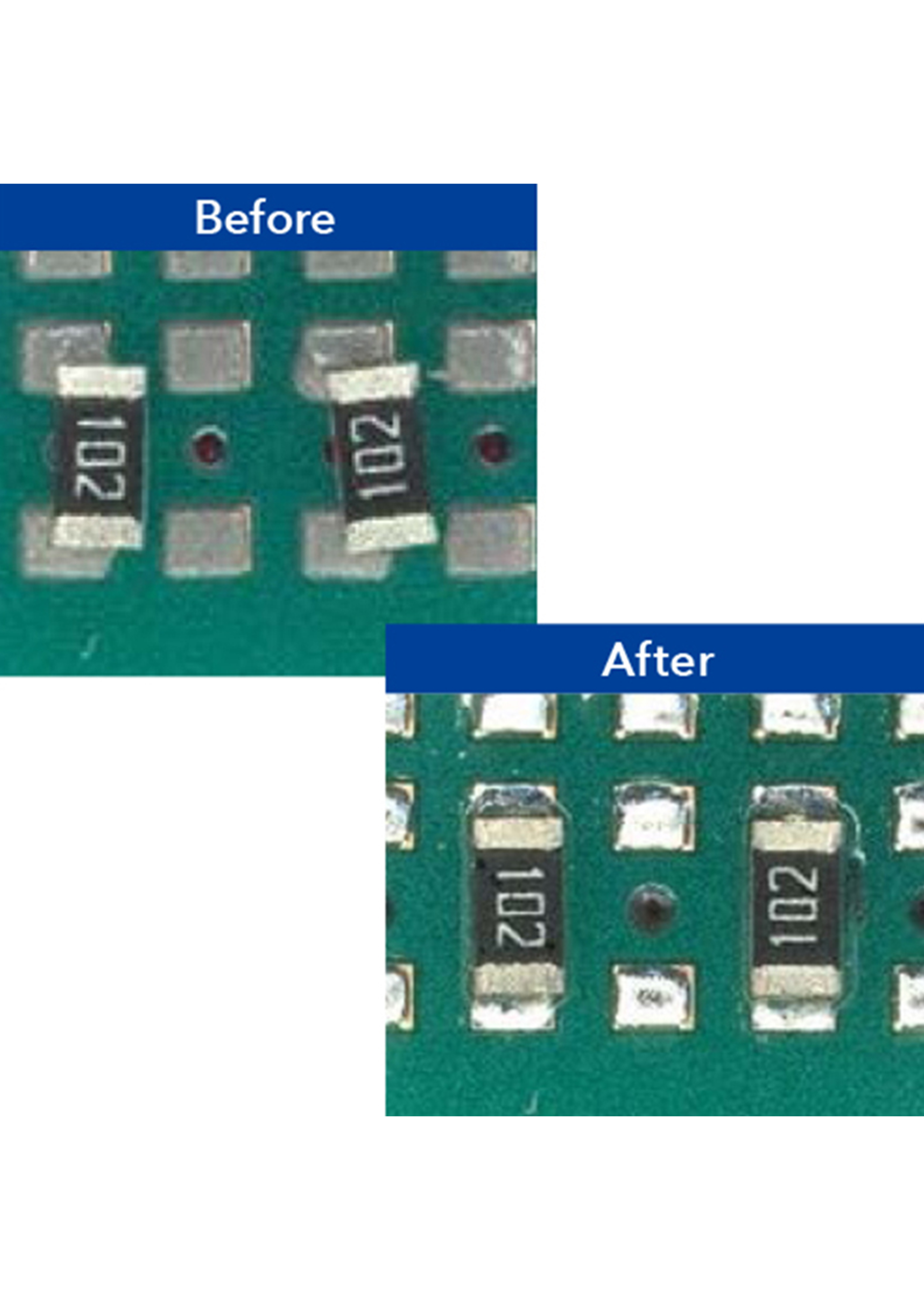

- Low curing temperature mitigates damage to the PCB and the components. JU-90LT-3 cures at low temperatures around 90-100℃, reducing the level of oxidation for the components and substrate. It enables improvement in the overall product quality and first time product quality.

- Stable dispense shape and height, superior heat slump resistance. Dispense shape of JU-90LT-3 is stable during continuous dispensing. The dispense shape and height after 10000 shots are practically the same as the initial shots. Furthermore, the diameter of a dispensed adhesive was only approx. 4.7% larger after being cured at 90℃ for 90 sec. (**according to our in-house test)

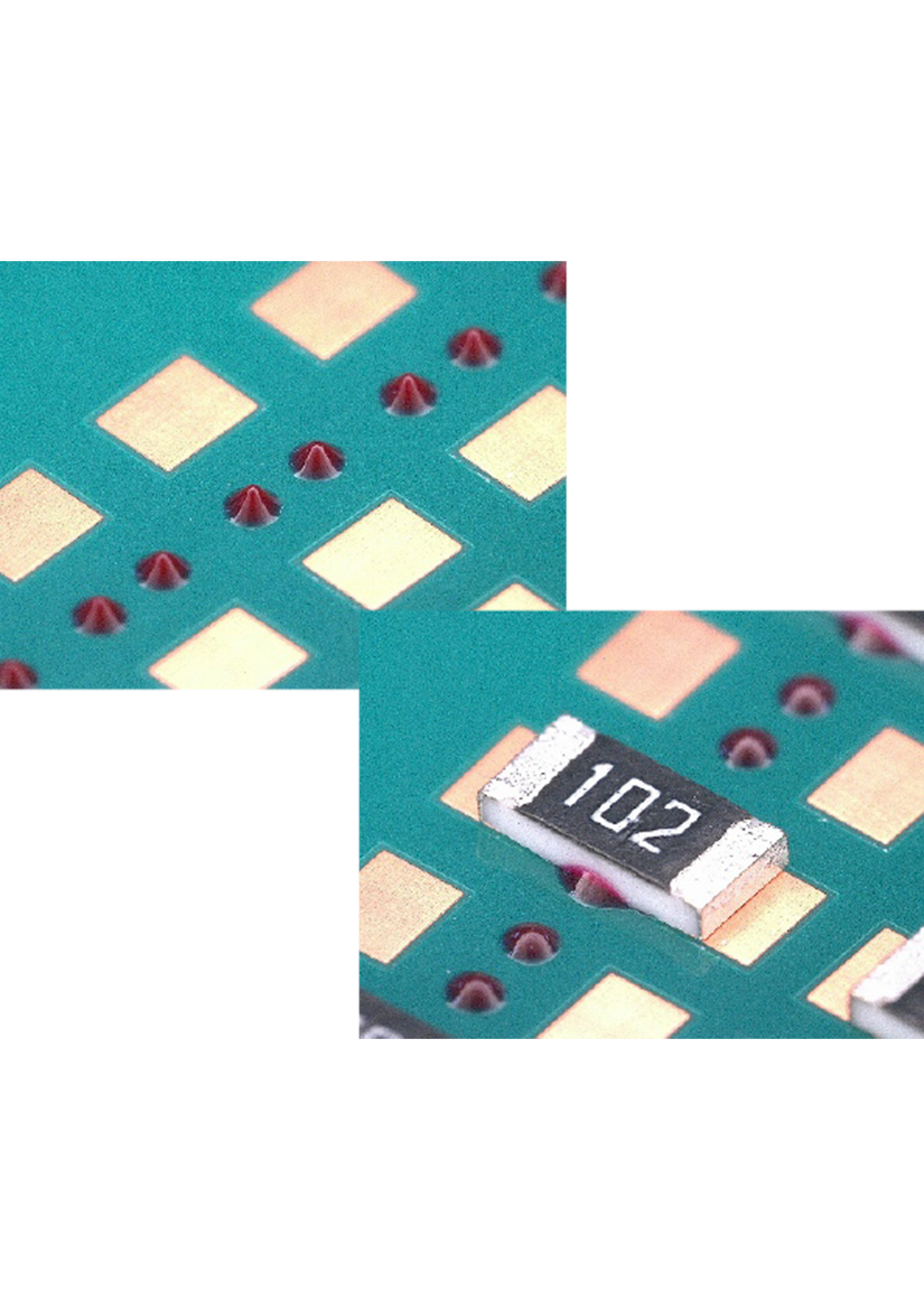

- Excellent electrical reliability after curing, suitable for fine-pitch patterns. JU-90LT-3 after curing shows good surface insulation resistance, making it suitable for use in fine-pitch patterns. In the biased humidity test with temp. 85℃ and humidity 85%, JU-90LT-3 indicates good insulation resistance well after 1000 hours without any trace of electrical migration.

- Specifications

| Model | JU-90LT-3 |

|---|---|

| Composition | Epoxy resin |

| Viscosity(Pa.s) | 65 |

| Shelf life (0-10℃) | 6 month |

| Product Category | Heat Curable SMT Adhesive |

| State / Color | Paste, red |

Same Category Products